To introduce these thread: this is a discussion of a hull form I've adapted to welded metal, feel free to suggest more of this, less of that, and whatever else you 'see' (beauty is in the eye of the beholder??) so that we can explore this hull form. I'm not selling plans, and AAB.com is not -through me- finding fault with this or any design or advocating anyone pay any attention to my opinion: which is all that is shown here.

About the images. I'm drawing in Delfship or modeling the hull form, then I export to SketchUP (*.dxf out; then in) and smooth the surfaces with tools there, sometimes things are faceted, that is- lines that should be curves are segmented or 'hogged' if the boat were real. That is because of the resolution I'm posting, these are not, of course, photo realistic images, they're sketches for the purpose of discussion among like minded metal boat people. If you find faults in the images, I'd be happy to try to explain them, but generally I'm trying to make images for discussion and not trying to provide a final polished hull model for building purposes.

Please don't confuse models and image files with boat plans. There are no plans, I don't sell plans, and AAB is not selling plans for these images. If you want a panga hull in metal please begin communications with one of the members or sponsors here who build full time, and working with them approach a design office able to do this level of work and see what is implied by this level of multi-surface complexity in welded aluminum.

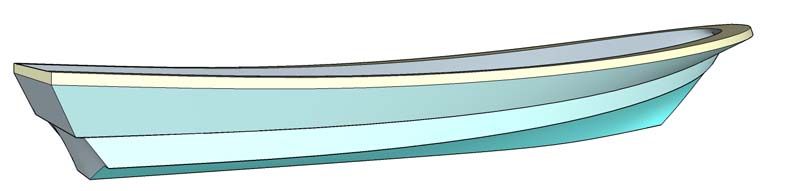

As usual with my online illustrations I've separated surfaces by color since "shades of gray" is what we get from aluminum surfaces in many images and that, as we all recognize, is the euphemism for vaguery and that is after all why I took time to make the sketches in the first place: to increase information exchange and avoid being vague! (:banghead: )

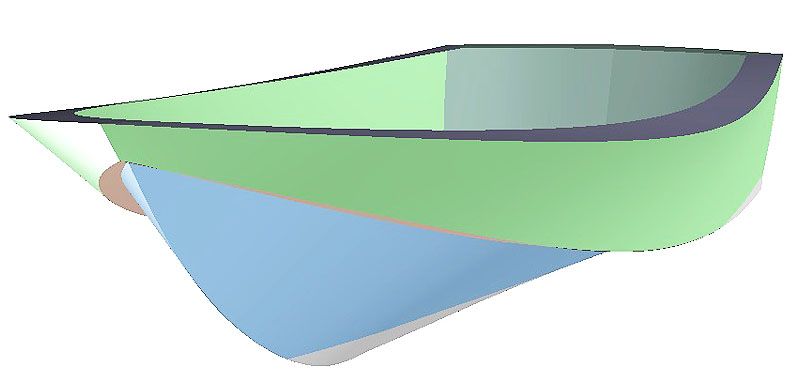

Here, some of the characteristics of this hull form are shown in a potential metal version. The very upswept bow, the topsides are divided into two different panels of at least two different angles to the waterline (flam). Where the upper panel toward the bow achieves an almost horizontal lean out to the bow would bury to a point but at that upper level along the bow stem the waterline will add 40 to 60% area in a few inches of immersion thereby almost assuring no load in this skiff could 'bury' the bow.

Now, if you have a fore deck, a cabin, or little to no load (non-commercial fishing) then you may not need this bow, but that is a panga feature.

Next is the very sharp and "pointy" forefoot, below the first chine flat, and last there's a flat bottom running aft at the centerline.

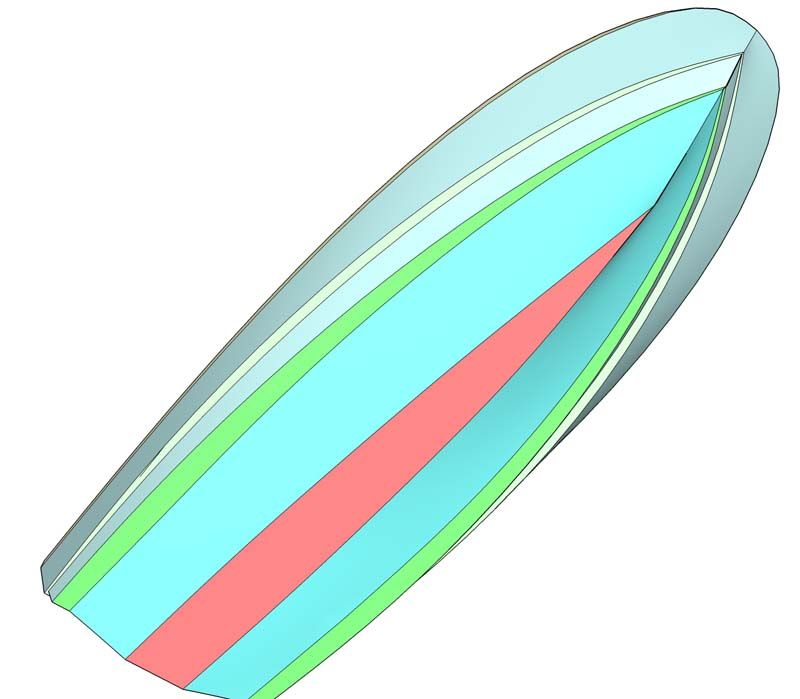

Looking from under the hull you can see that I put chine flats along the entire hull between the various flat panels. This allows the panels to fit together but each transition works as a spray rail, a longitudinal stiffener and to facilitate the changes in the interface seam between the two panels. This is similar to the plastic hulls but is a building aid, as well as a performance aid in metal, where in plastic, all the goops go in the mold together so they don't need these flats as much.

red is the long triangular flat about which there is more malarky online than can be quoted. It won't make the hull perform any magic but it will allow it to beach without tipping over, which I think is why its there.

Each chine and plank upward is colored for clarity.

Back to the bow, if you spend a few minutes thinking about how the waterlines grow as they are raised up this hull, meaning as the bow is immersed into a wave face or loaded with cargo/fish, then you can see why this is such a sea boat. There's almost no way to board a wave since the boat would pitch up by the bow farther and farther as it was immersed deeper and deeper. Note this will slow it down as the vector UP is canceling the vector FORWARD, but up is dry so I'd give up a little speed if I was 30 miles offshore.

I've put a taller transom on this model compared to the warm water versions, but that's not needed just what I did in this series of sketches. Not an unattractive sheer in my eyes, and one of the reasons this boat is so pretty in my opinion, many builders of current metal boats seem not to value sheer, I find that a loss to their designs and builds.

I here all this nonsense online about working nets over this bow but think that is malarkey, I think nets would be worked over the low point of the waist and the bow is high to protect the net, the fishermen and the load while working in the low point? Just my take.

A look 'under her skirts' so to speak. The flat in the centerline is flanked by decent deadrise and that increases to the bow. It was sort of a compromise to find a developable plate form that would result in this shape, but there are solutions. The bow has an optical 'illusion' that looks hollow but isn't!

And a section to show the idea of the boxed gunwale that completely eliminates any need for transverse vertical framing, but there is no framing in the bottom shown either. This helps to see what I am suggesting is a way to solve the hull forms various characteristic surfaces in metal.

All remarks welcome, including anyone with enough experience with these hulls to help guide the proportions, this is somewhat wider than is normally seen in this hull type.

Some of my previous remarks about why this hull is not yet made in aluminum will probably show up here. There are lots more full length hull seams to cut, tack up /assemble and WELD! the cost for a same size hull will be roughly half again to double the 'five plate' boat designs.

Cheers,

Kevin Morin

Kenai, AK