Welds

Welds

G'day folks.I've been looking at a lot of boats on this site and in particular the welds(I'm a welder).It looks to me that a lot of the welds,especially on the cabs are made with tig as opposed to mig.Is this so the welds do not have to be ground as tig is a lot neater.To me it would add a lot of time to the build process as tig is quite slow in comparison.Maybe Jay could enlighten me as to the % of mig to tig on his boats.It certainly is a good look.Cheers,Dan.

- JETTYWOLF

- Contributor/donator/Location Nazi

- Posts: 6074

- Joined: Sun Jan 06, 2008 9:11 pm

- 16

- Your location: JACKSONVILLE FL USA

- Location: Tree-hugger, USA...they call it FLA.

Being that I never really knew any better, the first time I saw a boat being "ground upon", I was wondering what the heck they doing that for?

I think it was a Aussie boat too...

I know mine a Pacific has no grinding done, and all the welds are visible, and very pretty.

NOT being a welder, (I just fish once in awhile.) I don't know any difference. So keep on going, and enlighten us or maybe just me. On the differences in systems, and the hows and why a grinder hits the welds.

I'm up for learning something new!

I think it was a Aussie boat too...

I know mine a Pacific has no grinding done, and all the welds are visible, and very pretty.

NOT being a welder, (I just fish once in awhile.) I don't know any difference. So keep on going, and enlighten us or maybe just me. On the differences in systems, and the hows and why a grinder hits the welds.

I'm up for learning something new!

-

Chaps

- Donator '09

- Posts: 2246

- Joined: Sun Jan 13, 2008 12:19 am

- 16

- Your location: Seattle, WA

- Location: Seattle, WA

It seems the more expensive the boat the more tig welding, especially in the highly visible spots or where thin materials are being used or where the welds are so short that mig would be too difficult.

However, more builders are using the pulsed or pulse-on-pulse mig machines which in the right hands can produce welds that the uninitiated will think are done with tig but are accomplished at mig rates of speed.

I'm a welding rookie but I'm getting there

However, more builders are using the pulsed or pulse-on-pulse mig machines which in the right hands can produce welds that the uninitiated will think are done with tig but are accomplished at mig rates of speed.

I'm a welding rookie but I'm getting there

1987 24' LaConner pilothouse workboat, 225 Suzuki

please view and like: https://www.facebook.com/bottompainting/

please view and like: https://www.facebook.com/bottompainting/

- Sculpin

- Posts: 905

- Joined: Tue Apr 22, 2008 10:10 pm

- 16

- Location: Vancouver Island(The Rock), British Columbia

Chaps is absolutely correct in a lot of the shops are using pulse and the newer technology of pulse on pulse. The latter actually is quite user friendly once set up right and produces almost tig quality welds. The machines are quite expensive and that may deter some shops from going that route. There is one builder here on the island that uses a wee little 200 amp CV machine with the old faithfull miller 30A 1 lb. spool gun with no pulse and produces amazing welds and does very minimal grinding. I think the operator has alot more to do with it than the process.

You may be quite right about the pulse mig.I have never used one but I may look into getting one as I may be finishing off a new hull and building the trailer for it out of ali.That is if I can sell mine in the current market.I think we grind a lot of our welds over here because the boats here are generally painted and smoothed out.I am going to go the unpainted route next time as I really don't think paint and ali mix that well.

-

Bullshipper

- Posts: 199

- Joined: Tue Jan 08, 2008 11:53 pm

- 16

- Location: Mexico

-

Chaps

- Donator '09

- Posts: 2246

- Joined: Sun Jan 13, 2008 12:19 am

- 16

- Your location: Seattle, WA

- Location: Seattle, WA

Bull,

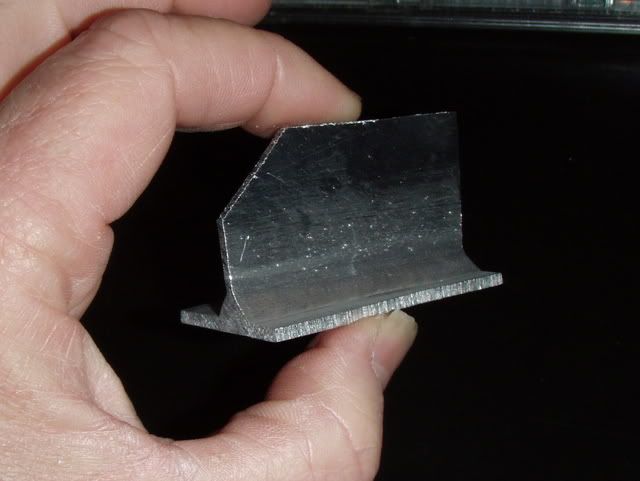

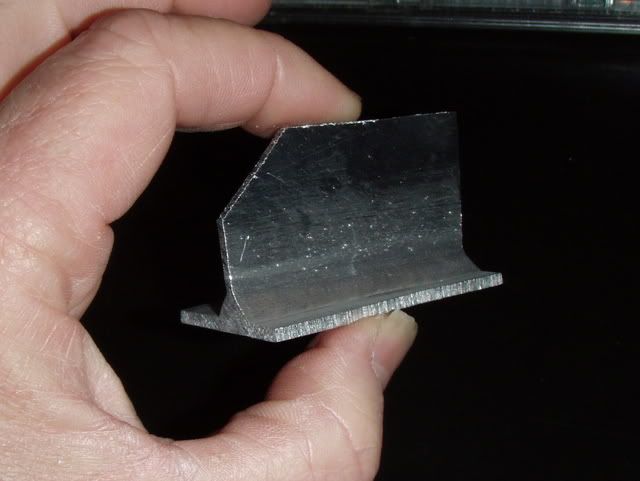

That pic I posted was a weld done with an even different mig mode called "power mode" on the Lincolns. The pulse will give the stacked dimes type of bead depending on your settings.

I found it, power mode on .080 (base plate) & .060 sheet:

That pic I posted was a weld done with an even different mig mode called "power mode" on the Lincolns. The pulse will give the stacked dimes type of bead depending on your settings.

I found it, power mode on .080 (base plate) & .060 sheet:

1987 24' LaConner pilothouse workboat, 225 Suzuki

please view and like: https://www.facebook.com/bottompainting/

please view and like: https://www.facebook.com/bottompainting/

-

Bullshipper

- Posts: 199

- Joined: Tue Jan 08, 2008 11:53 pm

- 16

- Location: Mexico

[quote="Chaps"]Bull,

That pic I posted was a weld done with an even different mig mode called "power mode" on the Lincolns. The pulse will give the stacked dimes type of bead depending on your settings.

I found it, power mode on .080 (base plate) & .060 sheet:

[img]http://img.photobucket.com/albums/v234/ ... /brkt3.jpg[/img][/quote]

That looks so good that grinding would be a waste of time.

That pic I posted was a weld done with an even different mig mode called "power mode" on the Lincolns. The pulse will give the stacked dimes type of bead depending on your settings.

I found it, power mode on .080 (base plate) & .060 sheet:

[img]http://img.photobucket.com/albums/v234/ ... /brkt3.jpg[/img][/quote]

That looks so good that grinding would be a waste of time.

Jettywolf,mig welds are produced via a constant stream of ali wire through a gun(handpiece)which is shrouded in an inert gas i.e. argon.This is a fast way of putting down weld metal and a pulse mig can give it visual characteristics akin to tig.Tig welding is done with a torch which transfers an electric arc from a tungsten electrode in the torch to the workpiece.This arc is also protected from the atmosphere by an inert gas.The heat generated forms a molten puddle in the metal and filler rod is fed in by your other hand much like oxy welding.This method requires better hand eye coordination and is a much slower process but is regarded as giving the best weld quality in the right hands.Over here I would say that 95% of any boat built would be migwelded.Small fittings and such would probably be tigged but the migs coming out today are getting pretty fancy and can do just about anything.You may have known all that but in case you didn't.Cheers,Dan.

-

IN2DEEP

- WON Super Star Donator '08, '09, '10, '11

- Posts: 638

- Joined: Sat Mar 15, 2008 1:07 pm

- 16

- Location: So. Calif.

Good thread, Danielw!

There's some good info being spoken here.

I hear the terms "mig" and "tig" talked about in regards to welding but didn't really know which was which.

Thank you for informing us "not" in the know :D

Sharing your knowledge is greatly appreciated.

Scott

There's some good info being spoken here.

I hear the terms "mig" and "tig" talked about in regards to welding but didn't really know which was which.

Thank you for informing us "not" in the know :D

Sharing your knowledge is greatly appreciated.

Scott

1989 22' Walkaround Cuddy Bayrunner

2001 115 Merc. 4 stroke/1988 9.9 Yamaha 4 stroke kicker

- Sculpin

- Posts: 905

- Joined: Tue Apr 22, 2008 10:10 pm

- 16

- Location: Vancouver Island(The Rock), British Columbia

Here is some info from the Lincoln site describing the different "modes" or settings for their model 350 MP multi purpose machine.

Advantage Lincoln

Arc Performance:

• Lincoln Chopper Technology® delivers high quality welds by increasing the control over the welding arc.

• Multi-Process capable — Welds MIG, flux-cored, stick, TIG, pulsed MIG, and advanced processes like Pulse-On-Pulse™ and Power Mode®.

• Pulse-on-Pulse™ improves cleaning action when welding aluminum and delivers a TIG-like appearance to the weld beads.

• Power Mode® maintains a stable, smooth arc for short arc welding on thin material – great arc length control for aluminum welding.

• Synergic control of voltage with wire feed speed allows you to set weld procedures with only one control for simplicity.

You can download different wave technology into this unit as well to customize it so to speak. I am a big fan of Lincoln Electric and think they are a great company period. Not buying out and taking over this and that just sticking to what they know best.

I am not familiar with the " Power mode" as Chaps showed the results in his picture. Looks pretty nice. The thing about TIG welding is the amount of heat concentrated in one area for a relatively long period of time compared to MIG welding on aluminum that may have some concerns for structural type welds on aluminum.

Advantage Lincoln

Arc Performance:

• Lincoln Chopper Technology® delivers high quality welds by increasing the control over the welding arc.

• Multi-Process capable — Welds MIG, flux-cored, stick, TIG, pulsed MIG, and advanced processes like Pulse-On-Pulse™ and Power Mode®.

• Pulse-on-Pulse™ improves cleaning action when welding aluminum and delivers a TIG-like appearance to the weld beads.

• Power Mode® maintains a stable, smooth arc for short arc welding on thin material – great arc length control for aluminum welding.

• Synergic control of voltage with wire feed speed allows you to set weld procedures with only one control for simplicity.

You can download different wave technology into this unit as well to customize it so to speak. I am a big fan of Lincoln Electric and think they are a great company period. Not buying out and taking over this and that just sticking to what they know best.

I am not familiar with the " Power mode" as Chaps showed the results in his picture. Looks pretty nice. The thing about TIG welding is the amount of heat concentrated in one area for a relatively long period of time compared to MIG welding on aluminum that may have some concerns for structural type welds on aluminum.

-

Bullshipper

- Posts: 199

- Joined: Tue Jan 08, 2008 11:53 pm

- 16

- Location: Mexico

The Lincoln MP is a nice unit but very expensive ($6K) once you incorporate the gun, especially for the hobbiest that might want to add accessories or repair an alloy hull.

I would sure like to know what economical square wave machines are available for 1/4" capable on a limited duty cycle with single phase power.

I would sure like to know what economical square wave machines are available for 1/4" capable on a limited duty cycle with single phase power.

Danielw and Wolfman on the Jetty. There are several reasons for grinding welds. Some welds are ground for appearance (flush or no seams showing) reasons, some for performance (drag) reasons, some for clearance (fitment) reasons, some for porosity or profile reasons, some for finish (paint) reasons, some for a smooth surface such as on a deck (plug welds deck to framing) or gunnel cap splice or somewhere where a dimensional (thickness) change is undesirable or where a transducer or water pick-up or such will operate better with less turbulence/air bubbles. Tig welding typically produces the strongest, most attractive welds at a slower pace/higher heat input than Mig welding and at higher labor and consumables cost. For control and welding things such as small pipes to consoles, decks, gunnels etc. tig is the ticket. Swinging a high

speed Mig gun around a pipe is challenging for good weld appearance and integrity. The merit of Mig is higher speeds, less distortion, lower labor and consumables costs, and a quicker learning curve. Both processes have their place and in capable hands produce a high quality product.

speed Mig gun around a pipe is challenging for good weld appearance and integrity. The merit of Mig is higher speeds, less distortion, lower labor and consumables costs, and a quicker learning curve. Both processes have their place and in capable hands produce a high quality product.

- JETTYWOLF

- Contributor/donator/Location Nazi

- Posts: 6074

- Joined: Sun Jan 06, 2008 9:11 pm

- 16

- Your location: JACKSONVILLE FL USA

- Location: Tree-hugger, USA...they call it FLA.

I had not a clue, either. And appreciated the quick lesson.IN2DEEP wrote:Good thread, Danielw!

There's some good info being spoken here.

I hear the terms "mig" and "tig" talked about in regards to welding but didn't really know which was which.

Thank you for informing us "not" in the know :D

Sharing your knowledge is greatly appreciated.

Scott

I have cheapy welder sitting on my work bench. No gas, but feeds electric, and wire thru a handle. Good for small fixes on motorcycles, and thats about it.

I have in the past used the Tig method where I worked, at lunch time I built grapnel jetty anchors from cold rolled round steel. I was given a 2 minute instruction and went and practiced. Didn't know the diference of what I was even doing.

I got good after a few hundred anchors. Never played with Aluminum, though. In my next life I want to go to welding school, then machining school, and then work for a boat builder.